What is a Water Chiller?

leading paragraph:

A water chiller is a vital piece of equipment for industries needing temperature control. Whether it's cooling machinery or keeping specific environments at optimal temperatures, water chillers are essential. Let’s explore what they are and how they work.

featured Paragraph:

A water chiller is a device that removes heat from a liquid (usually water) and then circulates the cooled liquid through a system to regulate temperature. They are widely used in industries such as HVAC, pharmaceuticals, manufacturing, and food processing.

Transition Paragraph:

Now that we have a basic understanding of water chillers, let's dive deeper into how they function and why they are so important for different industries.

How Does a Water Chiller Work?

leading paragraph:

Curious about how a water chiller actually operates? It’s more than just cooling water—it involves several components working together to ensure efficient heat transfer.

featured Paragraph:

A water chiller works by using a refrigerant system to absorb heat from water. The water is cooled, and the chilled water is then sent through pipes or coils to absorb heat from equipment or environments, keeping everything at the right temperature.

Dive deeper Paragraph:

The process of how a water chiller works can be broken down into several stages:

-

Evaporation: The chiller uses a compressor to circulate refrigerant through a cooling system. The refrigerant absorbs heat from the water in the evaporator. As the refrigerant evaporates, it absorbs more heat, cooling the water down.

-

Compression: The refrigerant, now in a gaseous state, is compressed in the compressor. This step increases the pressure and temperature of the refrigerant, which prepares it to release the absorbed heat.

-

Condensation: In the condenser, the hot refrigerant gas is cooled by either air or water. As it cools, it condenses back into a liquid state, releasing the heat it absorbed from the water.

-

Expansion: The liquid refrigerant then flows through an expansion valve, which reduces its pressure and temperature. This prepares the refrigerant to absorb heat once again, starting the cycle over.

Through these four stages—evaporation, compression, condensation, and expansion—the water chiller continuously cools the water and circulates it to various systems or machines that need temperature regulation.

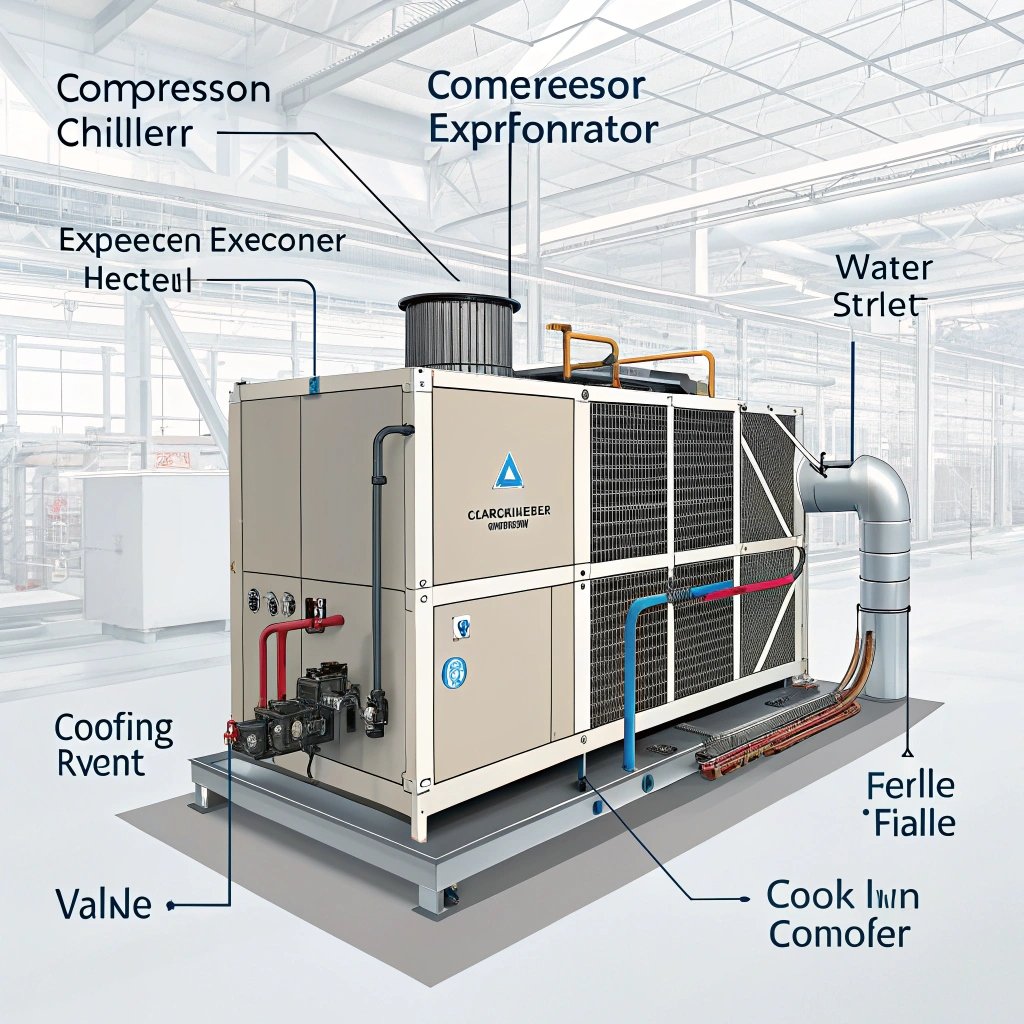

Key Components of a Water Chiller

Understanding the key components of a water chiller can help clarify how it works:

- Compressor: The heart of the chiller, responsible for compressing the refrigerant gas and starting the cooling cycle.

- Evaporator: The component that allows the refrigerant to absorb heat from the water.

- Condenser: A unit where the refrigerant releases the heat it has absorbed, usually through air or water.

- Expansion Valve: Controls the flow of refrigerant into the evaporator, allowing it to expand and cool.

Types of Water Chillers

leading paragraph:

Water chillers come in different types, and the one you choose depends on the needs of your operation. Let’s take a look at the two most common types.

featured Paragraph:

There are two main types of water chillers: air-cooled chillers and water-cooled chillers. Both types perform the same function but use different methods for cooling the refrigerant.

Dive deeper Paragraph:

-

Air-Cooled Water Chillers: These chillers use air to cool the refrigerant in the condenser. The refrigerant absorbs heat from the water and then releases it to the surrounding air. Air-cooled chillers are often used in environments where water availability is limited or where the cost of water is high. They are also easier to maintain and install because they don't require a separate water source.

-

Water-Cooled Water Chillers: These chillers use water to cool the refrigerant in the condenser. The refrigerant absorbs heat from the water and then releases it to a cooling tower or another water system. Water-cooled chillers are more efficient than air-cooled chillers, especially in larger applications, because water can absorb more heat than air. However, they require a reliable water supply and additional components like cooling towers.

Choosing Between Air-Cooled and Water-Cooled Chillers

When choosing between air-cooled and water-cooled chillers, the main factors to consider are:

- Energy Efficiency: Water-cooled chillers are generally more energy-efficient but may require more maintenance.

- Water Availability: If water is scarce or expensive, air-cooled chillers may be a better option.

- Installation Space: Air-cooled chillers are usually smaller and easier to install in areas with limited space.

Applications of Water Chillers

leading paragraph:

Water chillers play a vital role across multiple industries. Their versatility makes them ideal for a range of applications, from industrial cooling to food storage.

featured Paragraph:

Water chillers are used in a variety of applications, such as cooling industrial machinery, air conditioning systems, laboratories, and even in the food industry for keeping products at safe temperatures.

Dive deeper Paragraph:

Some common applications of water chillers include:

- HVAC Systems: In large buildings and commercial spaces, water chillers are often used in air conditioning systems to cool air efficiently.

- Manufacturing: Many industrial processes require precise temperature control, and water chillers are used to cool machinery, molds, and equipment.

- Food and Beverage: Water chillers are commonly used in the food and beverage industry to maintain the proper storage temperatures for products like dairy, meat, and beverages.

- Pharmaceuticals: For temperature-sensitive drugs and laboratory environments, water chillers ensure that the correct climate is maintained for research and production.

- Chemical Processing: Water chillers are used to maintain temperatures in chemical reactors to ensure the proper reaction conditions.

Conclusion

Water chillers are essential pieces of equipment in many industries, providing precise temperature control for a wide range of applications. Whether air-cooled or water-cooled, these devices help improve efficiency, protect equipment, and ensure safety in various processes.

Insights:

Choosing the right type of water chiller depends on factors such as energy efficiency, water availability, and installation space. Understanding these factors will help ensure that you select the best chiller for your specific needs.