What Are Air Cooled Chillers and How Do They Work?

leading paragraph:

Are you curious about how air cooled chillers work to keep large spaces cool? These systems are essential for many industries, but how do they actually function?

featured Paragraph:

Air cooled chillers are refrigeration systems that use air to cool the refrigerant. They are commonly used in industries where water is scarce or in places where water-based cooling systems are impractical.

Transition Paragraph:

Understanding the basic workings of an air cooled chiller can help you better appreciate its importance. Let’s break down how these systems operate and what makes them unique compared to other types of chillers.

What Is an Air Cooled Chiller?

leading paragraph:

An air cooled chiller is a system that cools liquids by transferring heat from the liquid to the surrounding air. But what makes them different from other types of chillers?

featured Paragraph:

An air cooled chiller uses ambient air to cool the refrigerant. As the refrigerant absorbs heat from the liquid it’s cooling, it passes through a condenser, where the heat is released to the air outside.

Dive deeper Paragraph:

Air cooled chillers are often used in applications where water is not available or where a water-cooled chiller would be too costly. Here's a closer look at how they function:

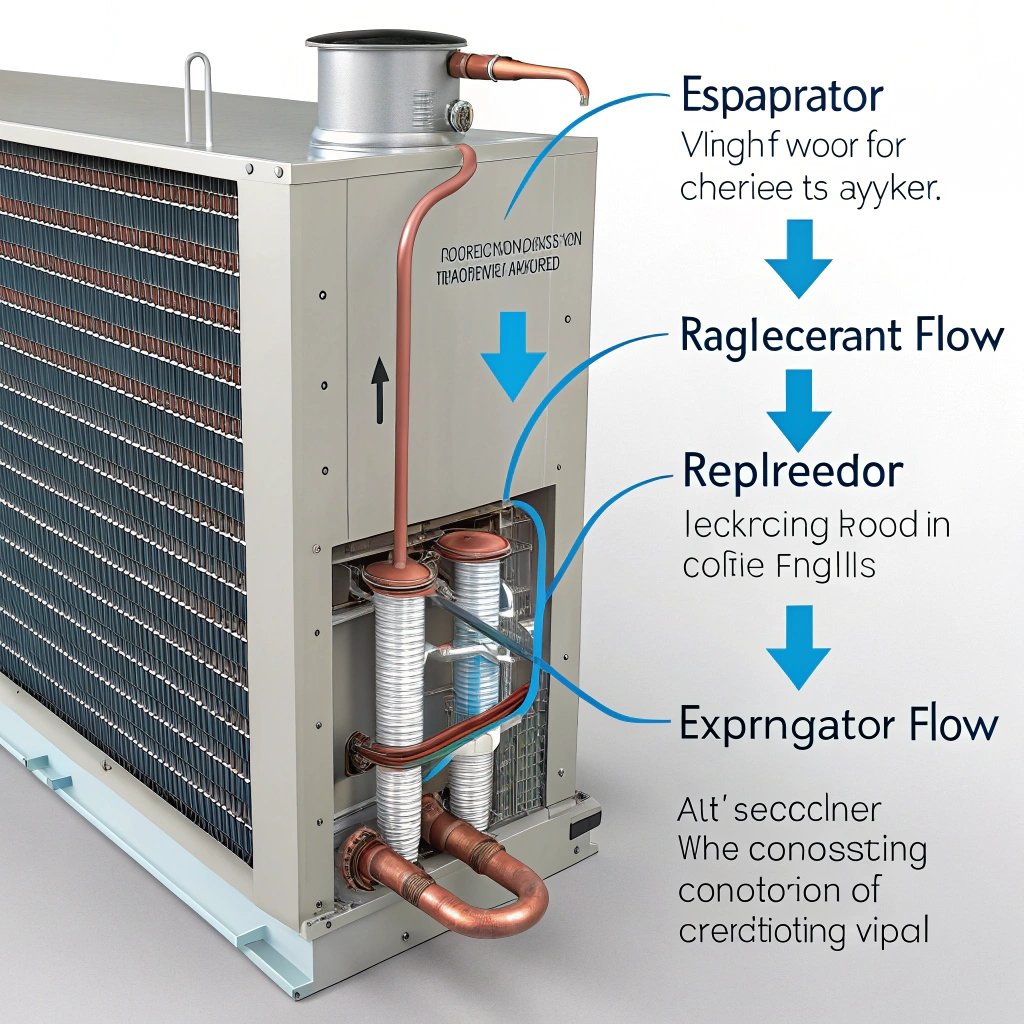

- Evaporator: The process starts when warm liquid enters the evaporator. The refrigerant inside the evaporator absorbs heat from the liquid, causing the refrigerant to evaporate and turn into a gas.

- Compressor: This gas is then sent to the compressor, where it’s compressed, increasing both its temperature and pressure.

- Condenser: The high-pressure, high-temperature gas flows into the air-cooled condenser. Here, the refrigerant releases its heat to the surrounding air, cooling down and returning to a liquid state.

- Expansion Valve: Finally, the refrigerant flows through the expansion valve, which reduces its pressure, causing it to cool even more before returning to the evaporator to absorb more heat.

The use of air instead of water in the cooling process makes air cooled chillers less complex and easier to maintain. Unlike water cooled chillers, they don’t require a cooling tower or water treatment, which makes them more environmentally friendly and cost-effective in certain conditions.

How Does an Air Cooled Chiller Differ from a Water Cooled Chiller?

leading paragraph:

You may be wondering, “What’s the difference between air cooled and water cooled chillers?” Let’s explore how these two types of systems differ and why one might be chosen over the other.

featured Paragraph:

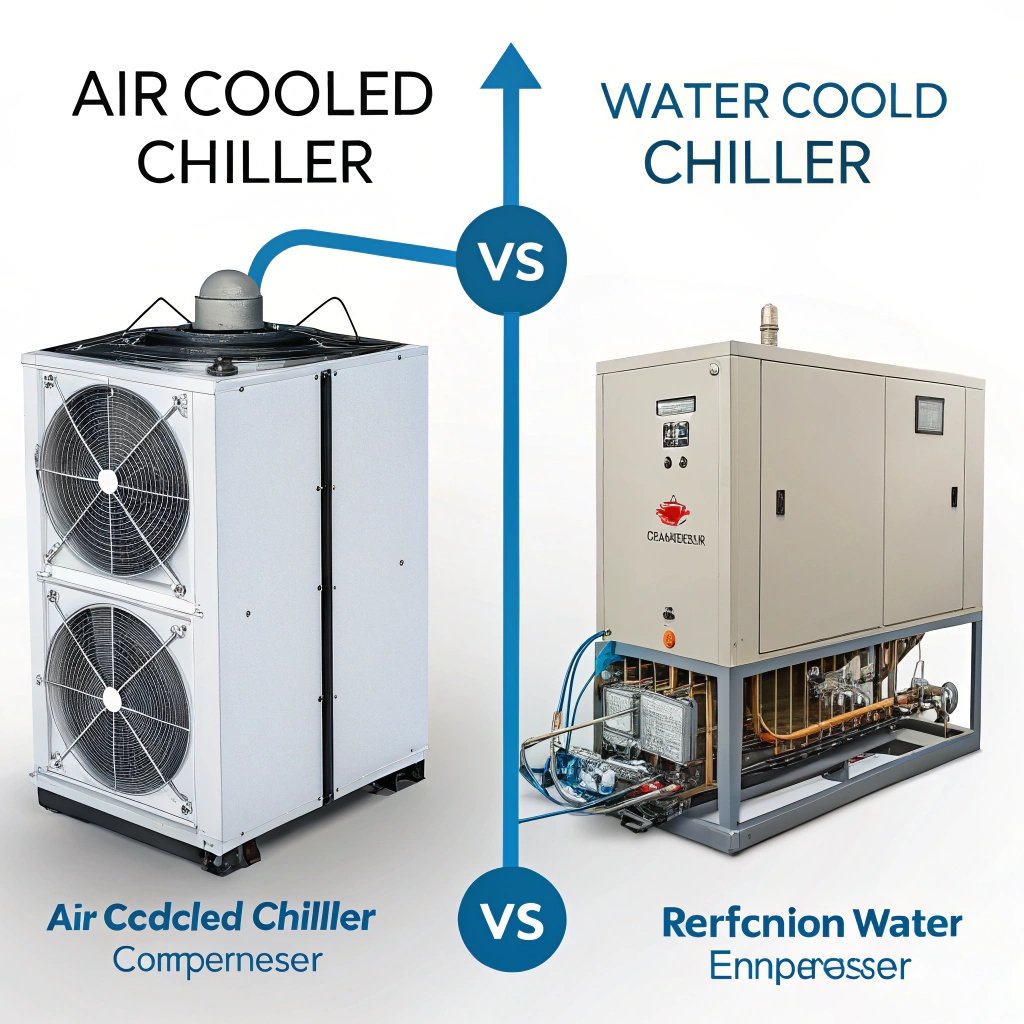

The key difference is that air cooled chillers use air to cool the refrigerant, while water cooled chillers use water. Water cooled chillers are often more efficient, but air cooled chillers are more common due to their simplicity and lower maintenance requirements.

Dive deeper Paragraph:

Both air cooled and water cooled chillers work by cooling refrigerants, but they differ in their cooling mediums and applications. Here’s a detailed comparison:

| Feature | Air Cooled Chillers | Water Cooled Chillers |

|---|---|---|

| Cooling Medium | Air | Water |

| Efficiency | Lower, more energy is required | Higher, more efficient in large systems |

| Maintenance | Low, easier to maintain | Higher, requires water treatment and cooling towers |

| Cost | Lower initial investment | Higher initial cost and operational cost |

| Environmental Impact | Less water usage, no cooling tower | Uses a lot of water, requires water treatment |

Air cooled chillers are ideal for smaller systems or places where water is scarce. They are also less expensive to install and maintain. However, they can be less efficient, especially in hot environments where the air temperature is high.

Water cooled chillers, on the other hand, are generally more efficient and perform better in larger-scale systems, especially in environments with access to a reliable water source. However, they require more maintenance and are more expensive to run due to the need for water treatment and cooling towers.

What Are the Advantages of Air Cooled Chillers?

leading paragraph:

Are air cooled chillers the right choice for your cooling needs? These systems offer several advantages, making them a popular choice in many industries.

featured Paragraph:

Air cooled chillers are cost-effective, easy to install, and have low maintenance needs. They are perfect for locations where water resources are limited or where simplicity is required.

Dive deeper Paragraph:

Here are some of the key benefits of air cooled chillers:

- Lower Installation Costs: Unlike water cooled chillers, air cooled chillers don’t require complex piping systems, cooling towers, or water treatment. This makes them easier and cheaper to install.

- Less Maintenance: With no need for water treatment, water cooling towers, or water pumps, air cooled chillers require significantly less maintenance.

- Environmentally Friendly: Air cooled chillers use air as the cooling medium, which means they don’t waste large amounts of water or require water-intensive systems.

- Versatility: These chillers can be used in various industries, from small commercial buildings to industrial sites, where water availability may be limited or unavailable.

- Energy Efficiency: Although they are not as efficient as water cooled systems, air cooled chillers are energy efficient enough for most small to medium applications.

Air cooled chillers are the go-to solution for many commercial and industrial applications where the cost and simplicity of operation are critical. They also have the advantage of being environmentally friendly by reducing water consumption.

Conclusion

Air cooled chillers are essential cooling systems that use air to cool refrigerant and remove heat. Their lower cost, ease of installation, and minimal maintenance make them ideal for a variety of applications.

Insights:

While air cooled chillers are not as energy efficient as water cooled chillers, their simplicity and cost-effectiveness make them an excellent choice for many industries. Whether you need a small-scale cooling system or have limited access to water, an air cooled chiller can meet your needs.